Speaking generally, operational excellence is created through the team’s state of mind.

Achieving it is a mindset change, as it is underpinned by the journey rather than the destination. Primarily it is about continuously investing and developing the right culture and tools to enable the most efficient flow of value to your customers. The journey of operational excellence is never actually achieved but is always strived towards. In this article, we examine the business principles and practices which help embed a culture of operational excellence, and how to implement systems to improve the flow of value onto the customer. Ultimately, teams achieving operational excellence will enhance their customer satisfaction and drive business growth.1. Be operationally excellent, rather than defining it as a transformation.

The terms operational excellence and business transformation become synonymous, but there is an important distinction. Operational excellence combines the principles of continuous improvement and best practice and uses them with streamlined processes, self-assessment and customer satisfaction metrics to achieve an enhanced result. Its philosophies are applied to daily activities and decisions. The approach aims to achieve sustainable improvement across performance metrics and requires dedication from every team member. It’s about creating small changes in your culture that achieve a flow-on effect. Business transformation is about making fundamental changes across a business’s processes, people and technology to deliver breakthrough results. There are often many change management projects which are deployed across departments to deliver the transformation. Embedding a culture of operational excellence equips each employee with the ability and tools to make individual decisions that positively impact the customer experience. Embedding a culture of operational excellence equips each employee with the ability and tools to make individual decisions that positively impact the customer experience.2. Embrace a lean value stream culture that focuses on speed, quality and customer experience.

People are at the core of making operational excellence (OE) a reality. When examining the end-to-end (E2E) value chain, making each team member aware of how their role fits within the entire process of providing value back to the customer will increase the flow of value. Work with each team member across departments to map out the series of steps that occur to provide a product or service. This process is referred to as value stream management. Value stream management is a lean business practice that is used to identify ‘what works’ and ‘what doesn’t’ in the features and functions of the product delivery life cycle, and how identifying the performance of each stage within this process can help improve the overall performance of the business. Using lean value stream management is how businesses enhance the customer experience, whilst also allowing you to monitor and manage and change introduced to the business with speed and without a reduction of quality. When you can see what needs to be changed, you can track its improvement.Map all your processes, focus on standardisation and empower your team.

When preparing to work towards operational excellence, standardisation and minimisation of abnormal activity prevents big problems. Using value stream mapping will allow your business to visualise, assess and alter the steps which are required to move a product through the supply chain. This added visibility, allows leaders to create a strong execution plan on how to implement change at each stage, and bring the team with them. Each incremental change requires daily monitoring to assess anomalies, inconsistencies and issues. It will also allow your teams to track breaks in processes that are hindering operation optimisation. Operational excellence can only be achieved when there is visibility on how things are working. Therefore, by minimising abnormal activity you can measure change and discard what is not working. Constantly analysing the adjustments and communicating those wins (and improvements) to the team creates team engagement. By doing this, you’re inviting your team to provide feedback and collaborate on the flow of value. Continuous process improvement will not work without direct engagement from the team. Therefore, mapping flows, planning change and maintaining standardisation requires all hands on deck. With a culture of OE, your team will be tackling the hurdles with a mindset of teamwork, problem-solving and a fundamental focus on the flow of value.Drive customer value with operational excellence

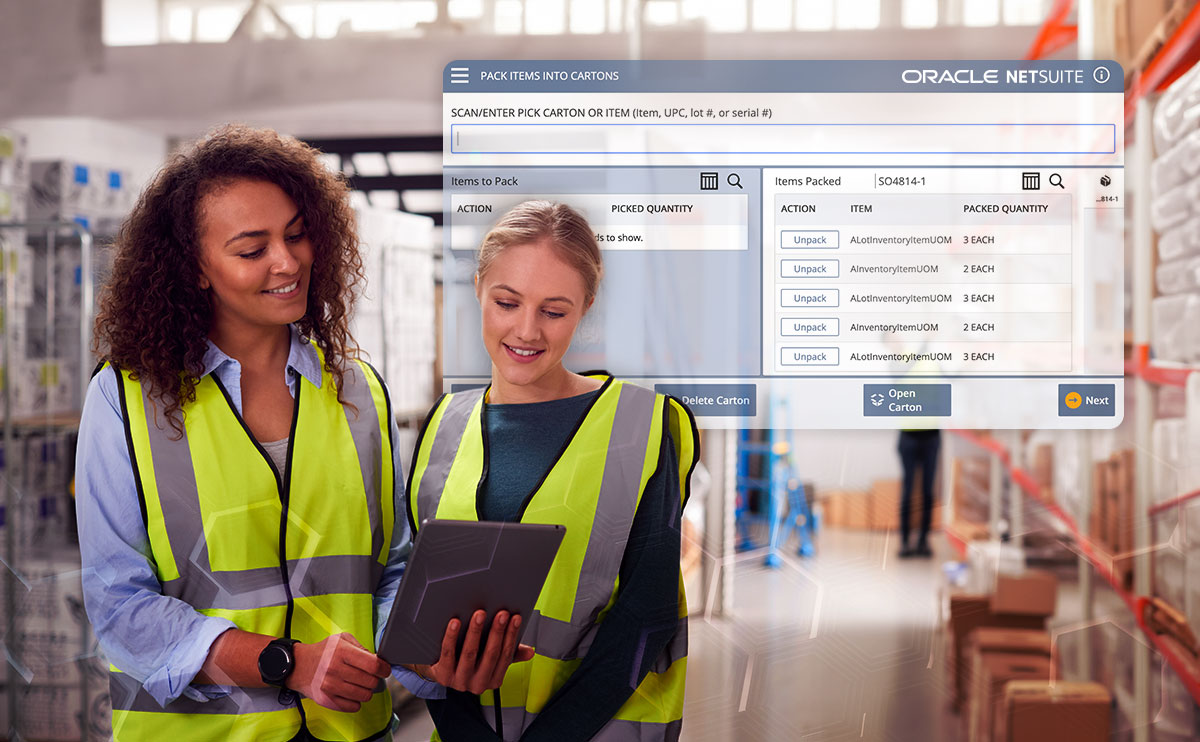

The decision to pursue operational excellence (OE) for your company is the first step on the journey. The next step is to cultivate a culture of collaborative approach, engagement and trust. Making sure every team member is engaged in the process and ensuring psychological safety will increase visibility across the end-to-end supply chain. Harnessing OE enables a culture of scalable improvement. Coupling this with good systems and software you can improve the speed and quality of delivery. Enabling faster innovation and business can only be achieved with a team that is committed to undertake change and see it through. If you’re motivated to create a business with operational excellence, the team at Klugo can show you the steps and provide the tools for sustainable change. Our team can provide a blueprint for both achieving operational excellence across culture and technology.About Klugo

NetSuite + NextService

Klugo’s vision is to unlock the full operating potential of our customers to maximise the value of their business. We do this by helping our customers achieve operating excellence using NetSuite + NextService, the world-leading cloud ERP and FSM business platform for small-to-medium-sized businesses.Need a specialist’s free advice?

Feel free to call an expert in operational excellence today. Find out how cloud-based technology can support and quickly adapt to your growth strategies.