The sales are flying in. More customers. More demand. It looks like business is about to start booming, but, with demand must come supply. Are you ready to meet those orders? To deliver on time, on budget and with as minimal disruptions as possible?

A common real-world representation of this is when we see empty shelves in supermarkets. Demand has not been truly met. Think of the toilet paper saga of 2020. A cheeky example, but true nonetheless. The moment you cannot supply a customer is the moment you lose them. It is a delicate balance trying to create an elastic type solution to supply and demand.

You must have a flexible system.

You don’t want to be caught holding the goods when demand runs out and you don’t want to be without stock when the market booms.

Post-2020, demand is building.

The IMF is expecting the economy to grow by 4.5% this year and 2.8% in 2022. Encouragingly, global growth has also been revised up by 0.5 percentage points to 6.0 per cent in 2021 and by 0.2 percentage points to 4.4 per cent in 2022.

IMF economic outlook.

This is good news, obviously. But how will local and international manufacturers deal with this supply chain change? Businesses will grow. Demand will increase.

Plan that demand and Demand Plan.

Demand planning solutions to align the supply chain with sales demand. Demand planning is the process of analysing historical sales with forecasted sales and coupling the demand with supply chain performance including lead times, availability, and quality.

A well-implemented demand plan ensures that inventory arrives just in time to supply customer orders with enough buffer to accommodate spikes in demand. Balancing working capital, storage and customer demand is a delicate exercise that can either lose customers or erode margin when it goes wrong.

So how do we achieve this balancing act? Here are a few simple tips:

- The key is to create an environment where you aim to align sales order shipping patterns with supplier delivery schedules. Whilst also considering forecasted sales demand. This allows your warehouse to increase stock turn whilst minimising stock obsolesce.

- Have a solid relationship with your suppliers to try and create a system where you accept purchase orders with multiple delivery schedules. The benefit of this arrangement is that it allows you to forward plan the procurement process and align goods with fulfilment dates. Ordering in bulk with a staggered delivery schedule as forward commitment allows you to take advantage of any bulk or volume pricing on offer.

- Have a deep understanding of your stock levels. This is a crucial visibility process that every business must have in place. It ultimately allows you to commit to orders with more confidence. This also plays into asking your customers to forward the order to reduce the chance of stock-outs.

- Available to Promise, this is a big one, commit to a customer order even when out of stock and confidently give them a shipping date. ATP uses Demand Planning data to assess booked sales demand and forecast demand against inbound orders and their expected delivery dates. Knowing expected stock levels at a future date allows you to generate sales rather than losing them, even when you are currently stocked out.

Get coordinated

The process of demand planning ultimately comes down to 3 very simple processes.

- Work with customers – Creating the terms and communication of your supply chain ultimately comes down to you. By understanding your customers’ business needs, requirements, quirks and frustrations, you can forward-plan with them. Visibility is key, and knowing their next step allows you to plan yours. Make it a priority to understand their business.

- Work with suppliers – Again, you need your deliveries to work according to your demand schedule. This comes down to visibility between you and your suppliers. They ultimately need to be able to fulfil the final step of the process, they need to know when things are moving from your end, and you need to understand their supply chain, even if only on a basic level.

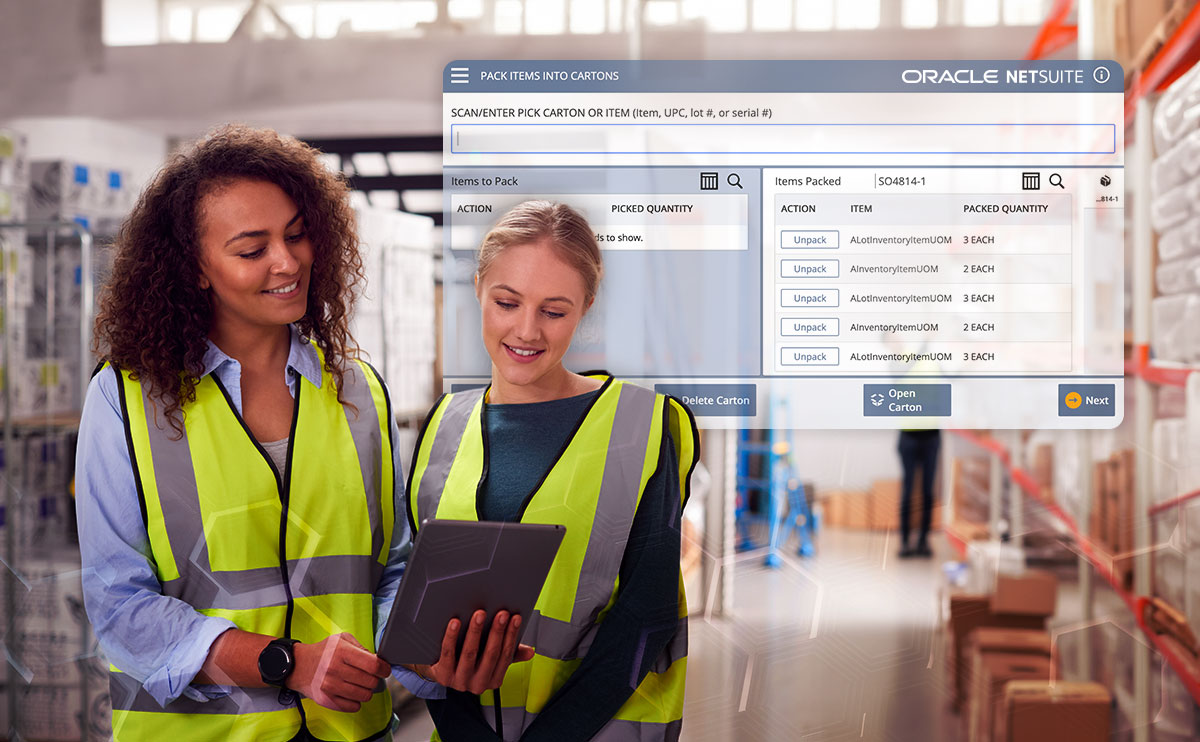

- A system that communicates – This comes down to having an effective Enterprise Resource Planning solution that includes demand planning, customer relationship management and procurement management.

A good enterprise resource planning solution with integrated demand planning will help your business stay ahead of the sales demand curve and keep all your customers.

To determine if demand planning will work for your business chat with our Klugo experts today.

About Klugo

NetSuite + NextService

Klugo’s vision is to unlock the full operating potential of our customers to maximise the value of their business. We do this by helping our customers achieve operating excellence using NetSuite + NextService, the world-leading cloud ERP and FSM business platform for small-to-medium-sized businesses.

Need a specialist’s free advice?

Feel free to call an expert in operational excellence today. Find out how cloud-based technology can support and quickly adapt to your growth strategies.